Category

Solenoid Valve Supplier

Home » Application

The hydraulic system of the wind turbine is actually the driving mechanism of the braking system, which mainly carries out the start-stop task of wind turbine. It is usually composed of two pressure holding circuits: one is to supply impeller brake system with accumulator, the other is to supply yaw brake system with accumulator. The job of these two circuits is to keep the brake system of the wind turbine under certain pressure when the wind turbine is running normally. When the pressure measured by the pressure sensor is less than the set value of the system, the PLC will control the start of the hydraulic station motor to compensate for the loss of pressure, so that the pressure value is always above the set value.

Impeller brake system of hydraulic system is working as follows. During normal operation, the opening and closing of the brake make the solenoid valve powered on, and the rotor brake is released. In case of emergency, brake opening and brake closing make solenoid valves powered off, the accumulator pressure oil enters brake calipers through brake opening valves, and the rotor brakes.

Impeller brake system of hydraulic system is working as follows. During normal operation, the opening and closing of the brake make the solenoid valve powered on, and the rotor brake is released. In case of emergency, brake opening and brake closing make solenoid valves powered off, the accumulator pressure oil enters brake calipers through brake opening valves, and the rotor brakes.

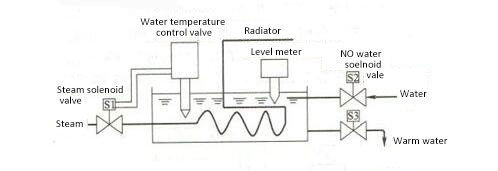

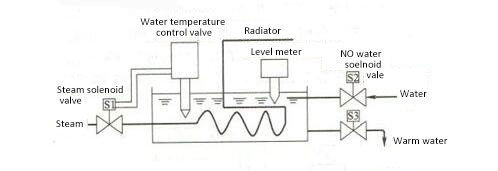

Solenoid valves can be used to control temperature and water level. As seen in the Figure below, when the temperature of the water tank is lower than the control temperature, the contact point of the temperature detecting element is connected, so that the steam solenoid valve S1 is opened. The steam pass through for the heat exchange to make the water temperature rise to the control point temperature, and the steam solenoid valve can be closed.

The water solenoid valve is always considered to be the simplest, but it is not. Water is divided into tap water, industrial pure water, industrial wastewater, irrigation water, seawater and other categories, whose corrosiveness and cleanliness are different, so different solenoid valves should be selected.

The central air-conditioning solenoid valve is a key component for regulating the cooling and heating of central air conditioner. We know that the solenoid valve consists of a solenoid coil and a magnetic core. When the central air conditioner starts up, the solenoid coil generates electromagnetic force to make the solenoid valve open, and then the refrigerant began to play a role. After the set temperature is reached, the power on the solenoid valve coil is off and the electromagnetic force also disappears, then the refrigerant circulation is turned off. In this way, the solenoid valve plays a role in adjusting the temperature.

The humidifier is equipped with a high temperature steam solenoid valve on the nozzle. According to the external switching signal, the power supply for the solenoid valve coil is switched on and off, and then control on-off of the humidifier. The solenoid valve can be used together with manual and electric actuating humidifiers to realize the automatic shutdown function of the humidifier at power off.

In the full set of the control system. the output device of the programmable logic controller (PLC) or the computer distributed control system (DCS) is usually adopted to control the solenoid valve or relay. Because of different causes, the anti-interference of the output devices (plate boards) is usually different. Before powering on for debugging, it is necessary to evaluate these circuits. The anti-inference measures should be adopted to avoid damage of the plate board channels or the whole plate board.

The solenoid valve can be divided into the DC solenoid valve and the AC solenoid valve according to the driving power. The solenoid valve is a typical inductive load. After the solenoid valve coil is switched on, the iron core might not yet be closed and its inductance might be very small. Under the condition, the starting current impulse of the AC solenoid valve will also be strong, which is around six folds to ten folds of the current at the steady state. Though the absolute value of the current is not large to cause any interference, it is necessary to fully evaluate whether the plate board volume can bear the current impact.

The solenoid valve can be divided into the DC solenoid valve and the AC solenoid valve according to the driving power. The solenoid valve is a typical inductive load. After the solenoid valve coil is switched on, the iron core might not yet be closed and its inductance might be very small. Under the condition, the starting current impulse of the AC solenoid valve will also be strong, which is around six folds to ten folds of the current at the steady state. Though the absolute value of the current is not large to cause any interference, it is necessary to fully evaluate whether the plate board volume can bear the current impact.

Solenoid valve has found wide applications to industrial production, particularly in chemical industry. Apart from applying to the on-off control of water, air, neutral gases, and other gases and liquids compatible with solenoid valve materials, the solenoid valve can also be an indispensable part (3-way, 4-way and 5-way) of the safe interlocking protection system.

The basic operating principle of dry granulation is like this. Artificially add the material into the vessel, and use the PLC to control the solenoid valve and seal the vessel. Start the draught fan and blow in the wind to the vessel. Heating and filtering are required when wind is blown in. The wind blinds the materials to a boiling state. After the materials are boiled, the spray gun is used to spray sizing agent (mist spray) onto the materials. After spraying, the wind is continuously blown in to blow the materials dry.

Solenoid valves are widely used in industrial production and petrochemical industry. It is particularly common and important in the industry. Solenoid valves can be used for switch control of water, air, steam and other media. It is an indispensable executive component of safety interlocking protection system (three-way, four-way, five-way). The following is the application of 3/2-way normally closled (NC) solenoid valve used with pneumatic control valve in the industrial production.

In order to avoid failure of actions (fault safety) of the solenoid valve upon interlocking caused by power source faults, the solenoid valve is usually at a normally-closed (NC) state. To be specific, there is power connection when it is normal, and the power disconnects when the interlocking action happens. The other kind is a universal type, which can be connected with either the normally-closed or the normally-open. In the practical engineering process, the NC or the universal type is adopted.

In order to avoid failure of actions (fault safety) of the solenoid valve upon interlocking caused by power source faults, the solenoid valve is usually at a normally-closed (NC) state. To be specific, there is power connection when it is normal, and the power disconnects when the interlocking action happens. The other kind is a universal type, which can be connected with either the normally-closed or the normally-open. In the practical engineering process, the NC or the universal type is adopted.

A good irrigation system, without a complete set of control system, can hardly achieve the water-saving effect. Generally, the irrigation system relies on the advanced control system to save its water. In the control design, the water systems can be divided into different control units according to different regions and devices, such as the lawn spray irrigation, shrub drip irrigation area, shrub spray irrigation area. The same irrigation area is controlled by one water solenoid valve. The solenoid valve usually ranges from DN25 to DN50. Then, the water solenoid valve is divided into several irrigation groups according to the water supply capacity of the main supply water pipe. Irrigation by turns can be adopted to reduce the main pipe diameter and reduce the pipeline investment cost.

The main function of the solenoid valves in refrigerators is to transform the refrigerant flowing direction, control the refrigerating state at different indoor temperatures and optimize the refrigerating structure to achieve the ideal settings and to meet different user demands.

There are different types of solenoid valves. The currently prevailing solenoid valves for refrigerators can be divided into two types. The first type is the monostable solenoid valve, and the other type is the bistable solenoid valve. The bistable solenoid valve can be further divided into two types, including the two-position three-way type and the six-position five-way type. To install the refrigerator with two refrigerating compartments, the marked exit of the solenoid valve is the air exhaust end. To install the refrigerator with more than three refrigerating compartments, the working direction should be clearly distinguished.

There are different types of solenoid valves. The currently prevailing solenoid valves for refrigerators can be divided into two types. The first type is the monostable solenoid valve, and the other type is the bistable solenoid valve. The bistable solenoid valve can be further divided into two types, including the two-position three-way type and the six-position five-way type. To install the refrigerator with two refrigerating compartments, the marked exit of the solenoid valve is the air exhaust end. To install the refrigerator with more than three refrigerating compartments, the working direction should be clearly distinguished.

The solenoid valve is used in the refrigeration system to prevent the refrigerating fluid from the high-voltage part from entering the evaporator when the compressor stops. And it also avoids an excessively high low-pressure when the compressor is started next time so as to prevent compressor liquid hammer.

When the refrigerator reaches the set value, the temperature controller moves. At the moment, the solenoid valve losses the power. When the low-pressure reaches the set value of the compressor when the machine is switched off, the compressor stops operating. When the temperature of the refrigeration house rises to the set value, the temperature controller moves and the solenoid valve is powered on. When the low-pressure reaches the set value of the compressor, the compressor will be started.

When the refrigerator reaches the set value, the temperature controller moves. At the moment, the solenoid valve losses the power. When the low-pressure reaches the set value of the compressor when the machine is switched off, the compressor stops operating. When the temperature of the refrigeration house rises to the set value, the temperature controller moves and the solenoid valve is powered on. When the low-pressure reaches the set value of the compressor, the compressor will be started.