Category

Solenoid Valve Supplier

Home » FAQ

In practical design and application, there are two main types of common power supply for solenoid valves: AC (like 110V, 220V) and DC (like 12V, 24V). Due to high supply voltage and small voltage loss of cable resistance in the transmission process, AC power supply almost will not cause the solenoid valve drive voltage is insufficient, so that the solenoid valve can not operate. But 220 V AC cable can not be mixed with other instrument signal cables and needs to be laid separately, which brings a lot of inconvenience in design and construction. The 24 V DC supply cable does not need to be laid separately, but it is better to calculate the solenoid supply voltage before deciding to use a 24 V DC solenoid valve, especially in the case of long power supply distance. The following is an example of calculating the supply voltage of a 24V solenoid valve.

Sometimes, the water solenoid valve will fail, and we need to disassemble it to check where the problem it. How to disassemble a water solenoid valve? The procedures is as belows:

1. Close the front and rear gate valves of the main valve of the water solenoid valve.

2. Loosen the pipe joint screw on the main valve cover to release the pressure inside the water solenoid valve.

3. Remove all the screws of the water solenoid valve, including the nuts of the copper tubes in the control pipeline.

1. Close the front and rear gate valves of the main valve of the water solenoid valve.

2. Loosen the pipe joint screw on the main valve cover to release the pressure inside the water solenoid valve.

3. Remove all the screws of the water solenoid valve, including the nuts of the copper tubes in the control pipeline.

The pneumatic valve uses compressed air to control the diaphragm, bellows or cylinder, and by controlling the diaphragm, bellows or cylinder, to drive the valve stem to push the valve core to close and open.

The solenoid valve is a device that controls the opening and closing of liquid, gas and steam by energizing and de-energizing the coil.

The solenoid valve is a device that controls the opening and closing of liquid, gas and steam by energizing and de-energizing the coil.

Solenoid valves are often used for the switching of water, oil, steam, gas and other media. Solenoid valves are often used to cut off water, oil, steam, gas and other media. Now combined with the application of solenoid valves to share the experience of selection and use of solenoid valves, to help you maximize the life of solenoid valves and improve the reliability of solenoid valves.

Valves are a very common product, both in our lives and in production. For example, a faucet is a type of valve. However, some valves now are not required to manually switch on and off, but automatically controlled. The solenoid valve is such a product among them, and its material also is very much. The following is a brief introduction to the main materials and characteristics of the solenoid valve and thus it is helpful to choose a right one for different applications.

According to the working state, the solenoid valve products can be divided into normally open solenoid valves and normally closed solenoid valves. There is also a kind of solenoid valve, namely, self-retaining solenoid valves, also called normally open normally closed solenoid valves.

There are some faults in the actual installation and application of pilot-operated solenoid valves. For example, the pilot-operated solenoid valve doesn’t work properly, has lower fluid transmission efficiency, and has leakage or noises. What causes it? Maybe it is due to selecting a wrong model, inconsistency between the medium density and temperature and the valve, improper installation and so on.

The following is listed some problems of pilot-operated solenoid valve and the possible causes and troubleshooting.

The following is listed some problems of pilot-operated solenoid valve and the possible causes and troubleshooting.

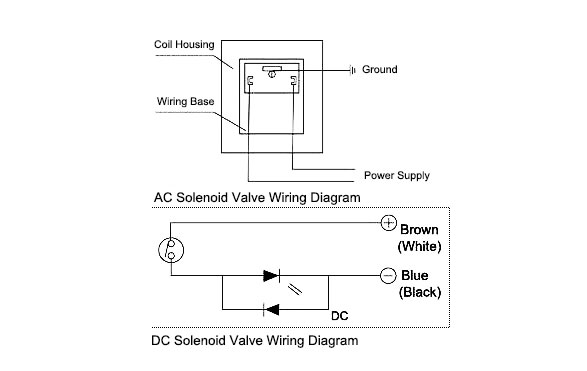

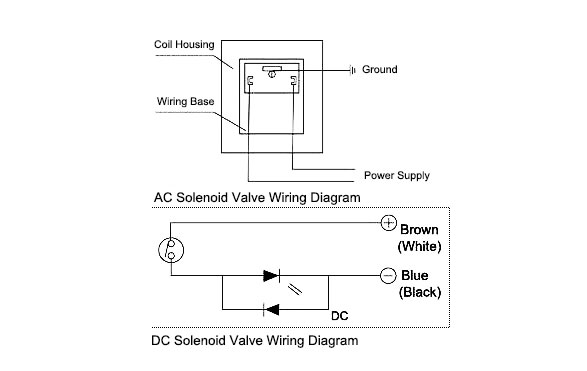

Wiring of the solenoid valve is simple. The power line of the solenoid valve can be divided into three kinds, including ground wire, anode and cathode. In terms of AC, the anode and cathode cannot be left unconsidered when wiring the solenoid valve. In terms of DC, attention should be paid to anode and cathode, and that the voltage should be the same. The wiring diagram of the solenoid valve is as below.

The solenoid valve and the electromagnet are similar to each other. Indeed, they have many similarities and also have differences between them. The similarities and differences between the solenoid valve and the electromagnet are briefly analyzed as below.

The solenoid valve is an industrial tool used to control basic automatic elements of fluids. As an actuator, it is used to adjust the direction, flowing quantity, speed and other parameters of the medium in the industrial control system. Electromagnet is a device which can generate electromagnetism after switch-on. The iron core is wrapped externally with the electric conduction winding consistent with its power.

The solenoid valve is an industrial tool used to control basic automatic elements of fluids. As an actuator, it is used to adjust the direction, flowing quantity, speed and other parameters of the medium in the industrial control system. Electromagnet is a device which can generate electromagnetism after switch-on. The iron core is wrapped externally with the electric conduction winding consistent with its power.

The steam solenoid valve and the water solenoid valve are two commonly-seen medium solenoid valves. To learn their differences can help us select the right product type.

The steam solenoid valve refers to the solenoid valve with the steam as the medium. The steam can be divided into two types: boiler steam - saturated steam and steam from the thermal plant - superheated steam. The saturated steam has relatively steady temperature and pressure. The temperature is lower than 250℃, and the working pressure is lower than 1.6Mpa. The superheated steam has dramatic changes of temperature and pressure. The maximum temperature can reach above 400℃, and the working pressure is lower than 4.0Mpa.

The water solenoid valve is applicable to the working medium, such as water or other liquids, to automatically control or realize remote control of the switch-on and switch-off of the working medium, such as water, hot water, cold water and waste water. It is applicable to the clean water transmission pipelines from different departments, such as dyeing and printing, clear water, electricity, petroleum, chemistry, metallurgy, textile, food, ship-building, medical care, environmental protection, and urban sectors.

The steam solenoid valve refers to the solenoid valve with the steam as the medium. The steam can be divided into two types: boiler steam - saturated steam and steam from the thermal plant - superheated steam. The saturated steam has relatively steady temperature and pressure. The temperature is lower than 250℃, and the working pressure is lower than 1.6Mpa. The superheated steam has dramatic changes of temperature and pressure. The maximum temperature can reach above 400℃, and the working pressure is lower than 4.0Mpa.

The water solenoid valve is applicable to the working medium, such as water or other liquids, to automatically control or realize remote control of the switch-on and switch-off of the working medium, such as water, hot water, cold water and waste water. It is applicable to the clean water transmission pipelines from different departments, such as dyeing and printing, clear water, electricity, petroleum, chemistry, metallurgy, textile, food, ship-building, medical care, environmental protection, and urban sectors.

The solenoid valve is an industrial equipment for electromagnetic control and an automatic basic element to control liquids. As an actuator, the solenoid valve is not confined to hydraulic and pneumatic control. When applied to the industrial control system, the solenoid valve can be used to adjust the medium direction, flow, speed and other parameters. The solenoid valve can work with different circuits to realize the expected control with the control precision and flexibility ensured.

The following part mainly introduces how to install the solenoid valve.

1. Read the product manual before installation. Check whether the product in line with use requirements. Keep key installation points in mind. Make good preparations for installing.

The following part mainly introduces how to install the solenoid valve.

1. Read the product manual before installation. Check whether the product in line with use requirements. Keep key installation points in mind. Make good preparations for installing.

The solenoid valves can be divided into the double-solenoid type and the single-solenoid type. The double-solenoid type has two solenoid coils, while the single-solenoid type just has one.

The slide valve of the single solenoid valve features the spring resetting. After the solenoid valve is disconnected with power, the solenoid valve automatically resets. The double solenoid valve requires the coil on the other side to get electrified before its transposition.

The single solenoid is switched on under constant power-on and air inlet, while the double solenoid is switched on at instant power-on.

The slide valve of the single solenoid valve features the spring resetting. After the solenoid valve is disconnected with power, the solenoid valve automatically resets. The double solenoid valve requires the coil on the other side to get electrified before its transposition.

The single solenoid is switched on under constant power-on and air inlet, while the double solenoid is switched on at instant power-on.