Category

Solenoid Valve Supplier

Home » General Purpose Solenoid Valves

ATOSolenoidvalve would like to introduce another series of 2/2 way water solenoid valve. This series is Normally Open type, that is, the solenoid valve is closed when the power is on, while it is open when the power is off. If the pipeline need to be open for a long time, this normally open solenoid valve will be your choice. The solenoid valve can be powered with 24V DC, and has brass body and NBR seal. With wide selection of port sizes, it can meet different needs of pipelines.

Water solenoid valves are suitable for water or liquid as working medium, which can automatically or remotely control the opening and closing of pipelines with water, oil, liquid and other working medium. Because the valve is sealed with rubber, the cleanliness of working medium is greatly reduced, and it features quick response time and high reliability.

This series are general purpose 2 way 2 position (2/2-way) solenoid valves. They have brass body and NBR sealing. The solenoid valves are Normally closed type, namely, the solenoid valve is open when energized and it is closed when de-energized. This series of solenoid valve features a wide range of port sizes to meet different sizes of the pipelines.

This series are general purpose 2 way 2 position (2/2-way) solenoid valves. They have brass body and NBR sealing. The solenoid valves are Normally closed type, namely, the solenoid valve is open when energized and it is closed when de-energized. This series of solenoid valve features a wide range of port sizes to meet different sizes of the pipelines.

Internal and external leakage is an essential element of safety. Other automatic control valves usually extend the valve stem and control the spool rotation or movement by an electric, pneumatic, hydraulic actuator. There is a problem to be solved of the dynamic sealing external leakage due to the long-tem movement of valve stem. But the solenoid valve works on the basis of the electromagnetic force to acting on the iron core sealed in the magnetic isolation sleeve. There is no dynamic seal, so the leakage is easy to block.

Soelnoid valves are made of different body materials and seal materials according to different media properties. The common body materials are brass, stainless steel, plastic and so on. The stainless steel solenoid valves are used in medical devices, analytical instruments, sulphur meters, water dispensers, humidifiers, semiconductor equipment, filling equipment, generators, kiln burners and other industries. Now we will introduce a series of stainless steel solenoid valve.

In the SMT machine, there is a very important component, namely, the solenoid valve. The solenoid valve is a very high-use accessory in the SMT placement machine and it is also a component that is more likely to fail. Therefore, the solenoid valve should be repaired in time when it fails and often maintained in the daily use of the SMT machine. Here are 5 tips how to maintain the SMT machine solenoid valve better, so as to ensure the SMT machine operating smoothly.

In the process of installation and use, solenoid valve fault occurs from time to time. The failure phenomenon usually shows as no inlet water or uncontrolled inlet water. When repairing, press the button of inlet water first to check if the solenoid valve is operating or not, or turn off the power supply directly and listen to the sound of water flowing or see if the water meter is still running. From these, check the state of the solenoid valve. If the state is abnormal, the following testing for solenoid valve can be carried out.

Steam solenoid valve can work in high temperature environment, which shows that the steam solenoid valve has super high protection performance. In addition, the steam solenoid valve is simple in structure, fast in action, small in power, light in shape, and also relatively wear-resistant, heat-resistant, condensation-resistant.Compared with other types of actuators such as control valves, steam solenoid valves are easy to install and maintain. However, attention should be paid when installing and maintaining the steam solenoid valve in daily use, so as to maintain the normal operation and prolong the service life of the equipment. Here are some tips for steam solenoid valve installation and maintenance.

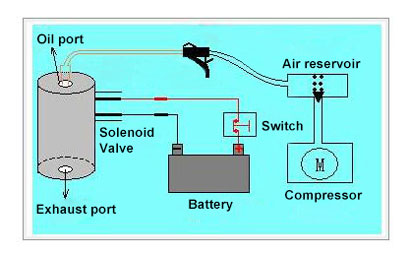

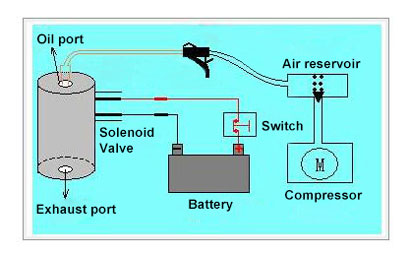

The solenoid valve in the automatic transmission is equal to the actuator, whose main function is to control the mechanical valve to finish the oil circuit exchange and the oil circuit flow control of the mechanical valve (pressure regulation).

The solenoid valve is an important actuating element to ensure normal operation of the automatic transmission. Different solenoid valve states are corresponding to different gears. The working state of the solenoid valve can directly influence the working status of the automatic gearbox. Meanwhile, inspection of the solenoid valve is also an indispensable link in the maintenance process of the automatic gearbox.

The solenoid valve is an important actuating element to ensure normal operation of the automatic transmission. Different solenoid valve states are corresponding to different gears. The working state of the solenoid valve can directly influence the working status of the automatic gearbox. Meanwhile, inspection of the solenoid valve is also an indispensable link in the maintenance process of the automatic gearbox.

Steam solenoid valve is a 2-way 2-position normally closed solenoid valve and can be used to control the on-off of the media including steam, water and air. It is direct-acting solenoid valve according to the working principle. With brass body material and EPDM seal material, steam solenoid valve can stand the working temperature from -5 to +180℃ (23~356℉). For more detail specifications, please check the below.