Category

Solenoid Valve Supplier

Home » General Purpose Solenoid Valves » How to Test Automatic Transmission Solenoid Valve?

How to Test Automatic Transmission Solenoid Valve?

The solenoid valve in the automatic transmission is equal to the actuator, whose main function is to control the mechanical valve to finish the oil circuit exchange and the oil circuit flow control of the mechanical valve (pressure regulation).

The solenoid valve is an important actuating element to ensure normal operation of the automatic transmission. Different solenoid valve states are corresponding to different gears. The working state of the solenoid valve can directly influence the working status of the automatic gearbox. Meanwhile, inspection of the solenoid valve is also an indispensable link in the maintenance process of the automatic gearbox.

In the following part, let's us introduce 3 effective inspection methods for the automatic transmission solenoid valve.

Static inspection of the automatic transmission solenoid valve

Static inspection of the solenoid valve refers to measurement of the solenoid valve resistance value and connection of the multimeter pen point with the solenoid valve contact pin to observe the resistance value on the instrument screen when the ignition switch is off. When the resistance value is higher than the rated value, it means the solenoid valve coil has been aging. When it is lower than the rated value, it means the solenoid valve coil interturn suffers short circuit. If it is infinitely large, it means the solenoid valve coil is in an open-circuit status. All the above states can suggest the solenoid valve has become invalid and must be changed for a new one.

Dynamic inspection of the automatic transmission solenoid valve

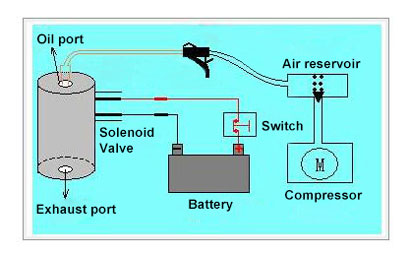

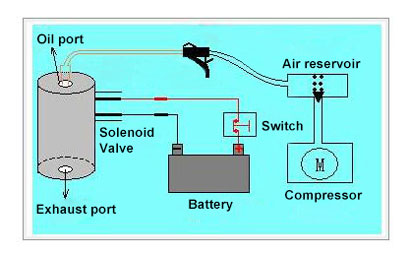

Static inspection is to simulate the practical working process of the solenoid valve and replace the oil pressure with the air pressure. Through manual excitation of the solenoid valve, whether the valve core movement of the solenoid valve is smooth and airtight should be checked. Impose the air pressure using the gas gun onto the working oil pole of the solenoid valve via the cone-shaped rubber head. Press on the control switch to realize repeated on and off of the solenoid valve, and then observe the circulation changes of the drainage port air flow. If the air flow exists constantly, it means the solenoid valve is poorly sealed. If there is no air flow, it means the solenoid valve has been blocked. If the air flow on and off is inconsistent with relevant standards, it means the solenoid valve is blocked now and then. If the air flow changes with the movement of the solenoid valve, it means the solenoid valve is normal.

Thermal inspection of the automatic transmission solenoid valve

The above two inspections cannot address problems by 100%. A large number of maintenance examples have proved that, even if the solenoid valve passes the above two inspections, it might be abnormal and less satisfactory when entering the thermal working status. The maintenance process might be stuck in different faults. Thermal inspection refers to the set temperature which can be reached when simulating the normal operation of the automatic gearbox. Heat the solenoid valve artificially using the air heater or other oil-powered or electric heating equipment to the normal working temperature. Then, conduct the resistance and dynamic pressure test. If the test results are normal, it means that solenoid valve has no problems. If the results are abnormal, the solenoid valve should be changed to a new one without hesitation.

Results of the above three inspections all suggest that the inside of the solenoid valve has been seriously worn-out and must be fully changed in the maintenance process. Of special note is that, before power-up test, characteristics and type of the solenoid valve should be clarified to see which is a gear-shift solenoid valve and which is a pressure-regulating solenoid valve. The resistance value of the pressure-regulating solenoid valve is generally small. If the 12V power is directly added thereto, the solenoid valve damage might be easily caused. During the process of test, one resistance of dozens of ohms is connected with the electric appliance loop of the pressure-regulating solenoid valve to limit the current flowing through the solenoid valve. This can ensure perfectly safe.

Experimental results suggest the resistance value of the general electronic valve at the cold state and the hot state differs by around three to five ohms. If the actually-measured value under the hot state is larger than the resistance difference, it means that the heat stability of the solenoid valve is poor. That heat makes something expand and cold makes it contract has been a common sense. As the internal temperature of the automatic gearbox rises, the surface temperature of the solenoid valve will rise as well, resulting in changes of the initial fit clearance. At the moment, if thermal expansion of the solenoid valve exceeds the limitation, the movement of the valve core will also be limited, and the original functions of the solenoid valve can be hardly given into full play.

The solenoid valve is an important actuating element to ensure normal operation of the automatic transmission. Different solenoid valve states are corresponding to different gears. The working state of the solenoid valve can directly influence the working status of the automatic gearbox. Meanwhile, inspection of the solenoid valve is also an indispensable link in the maintenance process of the automatic gearbox.

In the following part, let's us introduce 3 effective inspection methods for the automatic transmission solenoid valve.

Static inspection of the automatic transmission solenoid valve

Static inspection of the solenoid valve refers to measurement of the solenoid valve resistance value and connection of the multimeter pen point with the solenoid valve contact pin to observe the resistance value on the instrument screen when the ignition switch is off. When the resistance value is higher than the rated value, it means the solenoid valve coil has been aging. When it is lower than the rated value, it means the solenoid valve coil interturn suffers short circuit. If it is infinitely large, it means the solenoid valve coil is in an open-circuit status. All the above states can suggest the solenoid valve has become invalid and must be changed for a new one.

Static inspection is to simulate the practical working process of the solenoid valve and replace the oil pressure with the air pressure. Through manual excitation of the solenoid valve, whether the valve core movement of the solenoid valve is smooth and airtight should be checked. Impose the air pressure using the gas gun onto the working oil pole of the solenoid valve via the cone-shaped rubber head. Press on the control switch to realize repeated on and off of the solenoid valve, and then observe the circulation changes of the drainage port air flow. If the air flow exists constantly, it means the solenoid valve is poorly sealed. If there is no air flow, it means the solenoid valve has been blocked. If the air flow on and off is inconsistent with relevant standards, it means the solenoid valve is blocked now and then. If the air flow changes with the movement of the solenoid valve, it means the solenoid valve is normal.

The above two inspections cannot address problems by 100%. A large number of maintenance examples have proved that, even if the solenoid valve passes the above two inspections, it might be abnormal and less satisfactory when entering the thermal working status. The maintenance process might be stuck in different faults. Thermal inspection refers to the set temperature which can be reached when simulating the normal operation of the automatic gearbox. Heat the solenoid valve artificially using the air heater or other oil-powered or electric heating equipment to the normal working temperature. Then, conduct the resistance and dynamic pressure test. If the test results are normal, it means that solenoid valve has no problems. If the results are abnormal, the solenoid valve should be changed to a new one without hesitation.

Results of the above three inspections all suggest that the inside of the solenoid valve has been seriously worn-out and must be fully changed in the maintenance process. Of special note is that, before power-up test, characteristics and type of the solenoid valve should be clarified to see which is a gear-shift solenoid valve and which is a pressure-regulating solenoid valve. The resistance value of the pressure-regulating solenoid valve is generally small. If the 12V power is directly added thereto, the solenoid valve damage might be easily caused. During the process of test, one resistance of dozens of ohms is connected with the electric appliance loop of the pressure-regulating solenoid valve to limit the current flowing through the solenoid valve. This can ensure perfectly safe.

Experimental results suggest the resistance value of the general electronic valve at the cold state and the hot state differs by around three to five ohms. If the actually-measured value under the hot state is larger than the resistance difference, it means that the heat stability of the solenoid valve is poor. That heat makes something expand and cold makes it contract has been a common sense. As the internal temperature of the automatic gearbox rises, the surface temperature of the solenoid valve will rise as well, resulting in changes of the initial fit clearance. At the moment, if thermal expansion of the solenoid valve exceeds the limitation, the movement of the valve core will also be limited, and the original functions of the solenoid valve can be hardly given into full play.

Post a Comment:

You may also like: